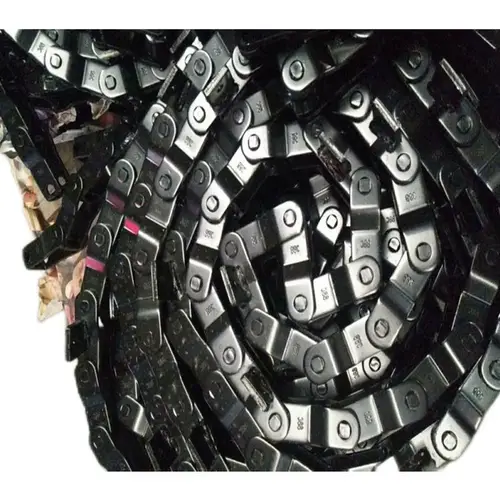

China Wholesaler Stainless Steel Roller Chain for Efficient Industrial Power Transmission

Steel roller chains are a crucial component in various industrial applications, including conveyor systems, packaging machinery, and agricultural equipment. At our company, we supply high-quality stainless steel roller chains that provide efficient and reliable power transmission over long distances with minimal maintenance requirements.

Overview of Steel Roller Chains

Steel roller chains are power transmission chains made up of a series of steel rollers connected by pins and plates, forming a continuous chain. They are designed to transmit power from one rotating shaft to another, usually with a sprocket or gear wheel attached to each shaft. As the chain rotates, the rollers engage with the teeth of the sprocket or gear wheel, causing it to rotate and transmit power to the other shaft.

One of the key advantages of steel roller chains is their ability to transmit high power levels over long distances with minimal loss of efficiency. They are also highly durable and resistant to wear and tear, which can help to extend their lifespan and reduce maintenance costs.

Applications of Steel Roller Chains

Steel roller chains are widely used in various industrial applications, including:

- Assembly lines

- Manufacturing equipment

- Mining equipment

- Construction equipment

- Agricultural equipment

- Conveyor systems

- Packaging machinery

- And more

Our stainless steel roller chains are of the highest quality and are designed to withstand even the most demanding industrial environments. Our expert team ensures that each chain is made with precision and attention to detail, so you can trust that our chains will provide reliable power transmission for your industrial applications.

Other Products

In addition to our steel roller chains, we also supply various other products for industrial use, such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, Pintle chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. We pride ourselves on providing high-quality products at preferential prices, with considerate services. Customers are welcome to customize drawings and samples to meet their unique industrial needs.

FAQs

1. What is a steel roller chain?

A steel roller chain is a power transmission chain made up of a series of steel rollers connected by pins and plates, forming a continuous chain. They are designed to transmit power from one rotating shaft to another, usually with a sprocket or gear wheel attached to each shaft.

2. What are the advantages of steel roller chains?

Steel roller chains can transmit high power levels over long distances with minimal loss of efficiency. They are also highly durable and resistant to wear and tear, which can help to extend their lifespan and reduce maintenance costs.

3. What are the applications of steel roller chains?

Steel roller chains are widely used in various industrial applications, including conveyor systems, packaging machinery, and agricultural equipment, among others.

4. What other products does your company supply?

In addition to steel roller chains, our company supplies various other products for industrial use, such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, Pintle chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more.

5. Can customers customize their orders?

Yes, customers are welcome to customize their orders by providing drawings and samples to meet their unique industrial needs.

All the content of this page is from the Internet. The content is only for reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks of the content. Our products are only suitable for after-sales replacement parts and not original spare parts. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.

Performance Characteristics of Pintle Chain

Pintle chains offer several performance characteristics that make them ideal for various applications:

1. High Strength: Pintle chains are known for their exceptional strength, allowing them to withstand heavy loads and high tension.

2. Durability: These chains are designed to be highly durable and resistant to wear, ensuring a longer lifespan even in demanding environments.

3. Flexibility: Pintle chains can easily adapt to different operating conditions and can handle both horizontal and vertical movements.

4. Easy Maintenance: These chains are relatively easy to maintain, requiring minimal lubrication and regular inspection to ensure optimal performance.

5. Noise Reduction: Pintle chains are designed to operate quietly, minimizing noise levels in industrial settings.

Types and Characteristics of Pintle Chain

Pintle chains come in various types, each catering to specific needs. Here are some common types and their characteristics:

1. Standard Pintle Chain: These chains feature a standard design with straight sidebars, suitable for general industrial applications.

2. Extended Pin Pintle Chain: This type of chain has extended pins that allow for easy attachment of additional components or accessories.

3. Hollow Pin Pintle Chain: These chains have hollow pins that can be used for feeding or conveying purposes in industries like food processing.

4. Combination Pintle Chain: Combination chains combine pintle and roller chain elements, providing increased flexibility and load-bearing capacity.

Advantages of Pintle Chain Made of Different Materials

Pintle chains can be made from various materials, each offering unique advantages:

1. Stainless Steel Pintle Chain: Stainless steel pintle chains are highly resistant to corrosion, making them suitable for applications in corrosive environments such as food processing or chemical industries.

2. Carbon Steel Pintle Chain: Carbon steel pintle chains offer excellent strength and durability, making them suitable for heavy-duty industrial applications.

3. Plastic Pintle Chain: Plastic pintle chains are lightweight, self-lubricating, and resistant to chemicals, making them ideal for industries requiring clean and quiet operations.

Application of Pintle Chain in Various Fields

Pintle chains find extensive use in various industries, including Material Handling, Waste Management, Industrial Applications, Agriculture, and Mining. Their versatility and reliability make them valuable in these fields, providing efficient and effective solutions for handling materials, managing waste, and ensuring smooth operations.

Future Development Trends and Opportunities of Pintle Chain Products

The future of pintle chain products holds promising trends and opportunities. As industries continue to evolve, the demand for reliable and efficient conveyor systems and material handling equipment will increase. This creates opportunities for the development of innovative pintle chain technologies, such as improved materials, advanced coatings, and enhanced designs. The growing focus on sustainability and energy efficiency also presents avenues for the development of eco-friendly pintle chain solutions.

How to Choose a Suitable Pintle Chain

Choosing the right pintle chain for your application requires careful consideration. Here are several aspects to analyze:

1. Determine Application Requirements: Understand the specific needs of your application, such as load capacity, speed, and environmental conditions.

2. Identify the Type of Chain: Consider the different types of pintle chains available and choose the one that best suits your application requirements.

3. Select the Chain Material: Evaluate the advantages of different materials and select the one that offers the desired properties for your specific application.

4. Consider the Chain Dimensions: Ensure the pintle chain dimensions match the requirements of your equipment and system.

5. Check Compatibility with Sprockets: Verify that the selected pintle chain is compatible with the sprockets used in your system.

Summary

In conclusion, pintle chains offer exceptional performance characteristics, including high strength, durability, flexibility, easy maintenance, and noise reduction. They come in various types and can be made from different materials, each offering specific advantages. Pintle chains find wide applications in Material Handling, Waste Management, Industrial Applications, Agriculture, Mining, and other fields. The future of pintle chain products holds promising trends, with opportunities for innovation and development. When choosing a pintle chain, it is essential to analyze application requirements, identify the type of chain, select the appropriate material, consider the dimensions, and ensure compatibility with sprockets.

Author: Dream